As a consequence, different temperatures in each mold zone cause considerable differences in tension. The effect of heat (radiation, thermal conduction) from the casting metal causes a thermal expansion of the mold material.

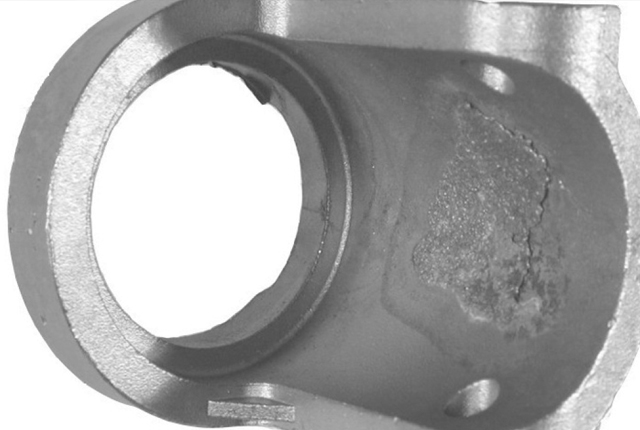

Veining is very often observed in resin-bonded cores (commonly also referred to as scabs). Veins are also caused by scaling, but unlike scabs they do not break open, but grow into the mold cavity as a consequence of quartz expansion, so that the casting metal flows into and fills the occurring gap to form a rib-like structure. scabs occurring at the upper horizontal mold wall, and bottom scabbing, which occurs below the casting metal flow at the mold bottom. Scabs ( Figures 1 and 2) are irregular metallic crusts on the casting surface caused by scaling they are only a few millimeters thick, usually have sharp edges and are firmly bonded to the casting.Ī differentiation is made between cavity scabbing, i.e. All these defects are clearly visible to the human eye, and generally result in rejection of the casting. Scabs are often accompanied by veining (mainly on core sections) and rat tails. Highly compacted sections in the mold are particularly at risk.

Scabs preferably occur over a larger surface at the top of the casting (mold cavity), but also at the bottom of the mold compartment. This mold sand-based casting defect occurs with castings of all casting materials which are produced in bentonite-bonded green molds (see Bentonite, Green sand mold).

0 kommentar(er)

0 kommentar(er)